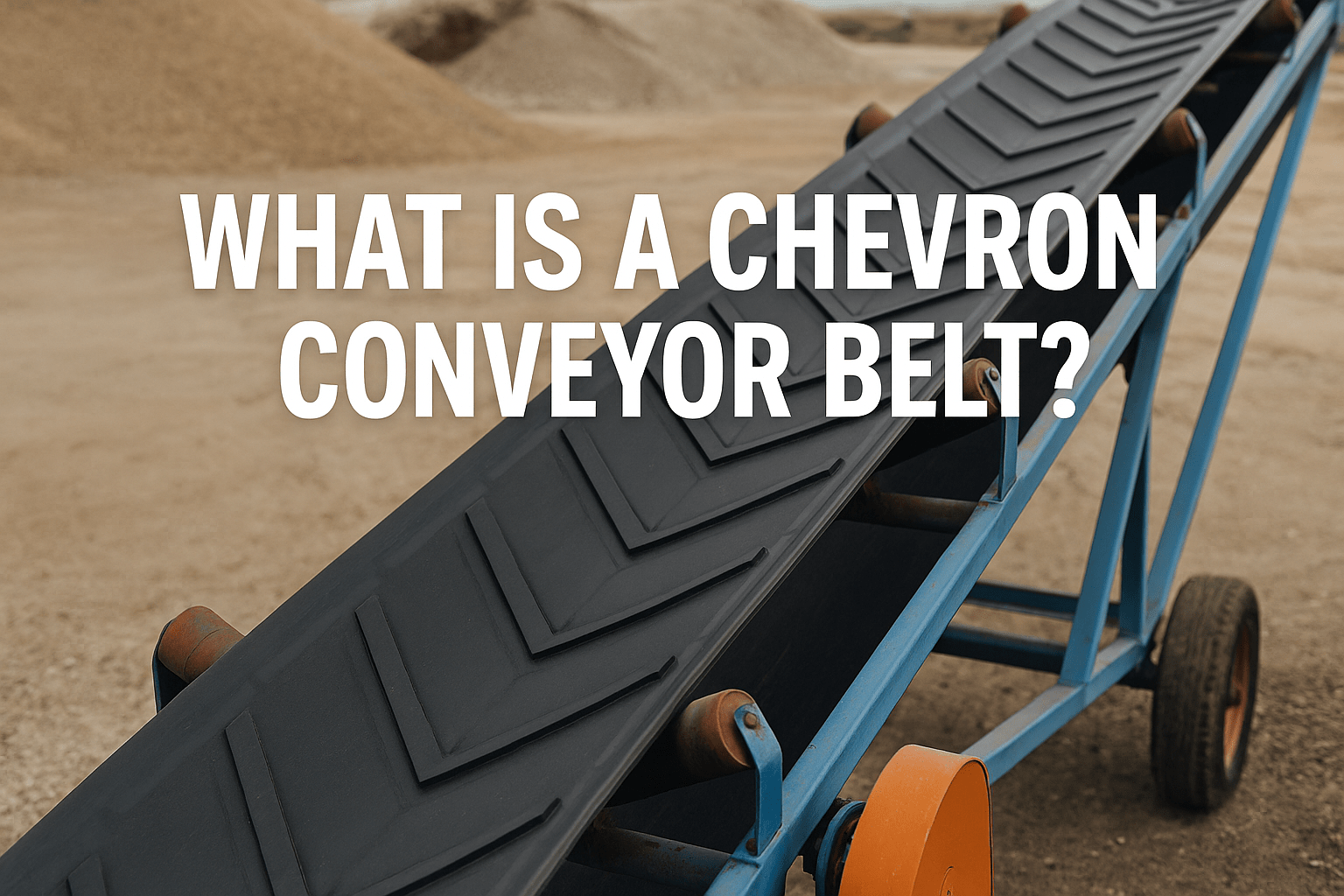

Industries that benefit most from chevron designs include mining, agriculture, bulk-material handling, recycling, construction, and some food and beverage operations (when food-grade compounds are used). Because chevron ribs can be engineered in varying profiles, they allow conveyors to operate at steeper angles than flat belts—often between 20° and 45°, and in some tailored cases, even steeper. Reliable chevron conveyor belt suppliers will offer guidance on matching rib profile to material particle size and moisture content to maintain throughput without spillage.

Chevron Belt Materials, Construction & Profiles

Chevron belts are manufactured using a variety of compounds—from robust rubber blends to specialized polymer compounds—bonded to textile or steel cord carcasses depending on strength and elongation requirements. The chevron pattern may be molded directly into the cover or formed as a separate cleated element. Important construction choices include cover hardness (measured in Shore A), carcass type (fabric vs. steel cord), and rib geometry. Each variable affects abrasion resistance, load support, and fatigue life. Trusted chevron conveyor belt suppliers will specify these parameters to match your conveyor speed, ambient conditions, and the physical characteristics of the conveyed bulk.

How to Choose the Right Chevron Profile

Material Behavior & Particle Size

Selecting the correct chevron rib profile requires understanding material behavior. Fine powders and dusty materials need a close rib spacing with lower rib heights to avoid embedding and bridging, while chunkier or wetter materials benefit from taller, more widely spaced ribs that create clear channels for material flow. Consider whether the material is cohesive (likely to clump) or free-flowing—this affects whether you need ribs that shed material quickly or ones that carry an even film across the belt. Work with suppliers who can perform on-site material assessments or accept samples for trial.

Incline Angle and Throughput

The steeper the incline the belt must conquer, the more aggressive the chevron geometry and friction profile should be. Higher throughputs also demand wider belts and stronger carcasses to avoid deflection and wrinkling. Many manufacturers publish angle-of-ride charts that correlate rib geometry to safe incline angles for certain materials; use these charts as starting points and validate with supplier expertise.

Installation Best Practices

Proper installation is key to the long life of a chevron belt. Ensure correct tracking alignment, proper belt tensioning (neither too loose nor over-tensioned), and a pulley system sized for the belt’s carcass and cover thickness. Avoid sharp transitional points at the head and tail pulleys—these are common trouble spots where chevron ribs can shear if routed over tight radii. When possible, install idler rollers with center grooves or crowned profiles designed for cleated or ribbed belts; this reduces lateral migration and improves stability under load.

Maintenance and Common Troubleshooting

Routine inspection and timely maintenance will dramatically extend service life. Look for early signs of wear such as rib rounding, edge delamination, or cracks at splice points. Keep the belt and conveyor frame free of buildup—material that lodges between ribs accelerates abrasion and promotes mis-tracking. Regularly inspect splices, cleat adhesion (for applied cleats), and pulley lagging condition. Common troubleshooting steps include realigning pulleys, cleaning return idlers, adjusting tension, and repairing or replacing worn ribs before they compromise the carcass.

Working With Suppliers: What to Expect

A reputable supplier should offer technical consultation, sample testing, clear product datasheets, lead-time transparency, and aftermarket support. They should be able to provide recommendations on carcass type, compound selection, and custom chevron geometries if necessary. Good suppliers also assist with installation training and troubleshooting during the warranty period. When comparing quotes, evaluate not only unit price but total cost of ownership—installation, expected wear life, downtime costs, and inbound freight all affect the real value you receive.

Cost Considerations & Total Cost of Ownership

While chevron belts typically cost more upfront than flat belts, their ability to convey at steep angles and reduce spillage can lower infrastructure costs (shorter conveyors, smaller transfer housings) and operational losses. Consider lifecycle factors: replacement interval, maintenance labor, energy consumption (heavier belts or higher friction sometimes increase motor load), and downtime costs. Ask suppliers for case studies or ROI illustrations that reflect similar operating conditions to your plant or site.

Customization and Specialized Options

Modern manufacturers offer tailored chevron solutions—varying rib heights, thermoplastic covers for low-temperature environments, food-safe compounds, oil- and chemical-resistant formulas, and reinforced splices for heavy loads. If your application presents unusual stressors—such as high-temperature exposure, extreme abrasion, or explosive dust—you’ll want a supplier that works closely with their compound engineers to qualify custom formulations and testing protocols.

Environmental & Safety Considerations

Choose compounds that minimize particle generation and that comply with applicable safety standards for your industry. For food handling, FDA- and EU-compliant materials are available; for mining or chemical plants, ask for data on resistance to oils, acids, and weathering. Ensure that belt cleaning systems (scrapers, brushes) are compatible with the chevron geometry so they remove buildup without damaging the ribs. Safety signage, guarding around nip points, and regular lockout-tagout procedures complete a responsible installation.

Frequently Asked Questions

- Q: Can chevron conveyor belts be used for food-grade applications?

- A: Yes—when made from food-grade compounds and manufactured in facilities that control contamination. Always request compliance documentation (FDA/EU) and verify that the supplier has appropriate traceability and sanitary design options.

- Q: How do I know whether to choose a fabric or steel-cord carcass?

- A: Fabric carcasses are common for lighter-duty conveyors and offer flexibility; steel-cord carcasses provide minimal elongation and are used for high-tension or long-span conveyors. The choice depends on load, belt width, service length, and desired elongation characteristics.

- Q: How often should I inspect chevron ribs and splices?

- A: Inspect visually at least weekly in heavy-use environments and monthly for lighter operations. Splice inspections should be part of a periodic preventive maintenance checklist and immediately after any abnormal operation or material spillage event.

- Q: Are chevron belts repairable on-site?

- A: Minor cuts, gouges, and edge damage are often repairable with approved adhesives or vulcanizing patches. Major damages or compromised splices usually require professional repair or full replacement to maintain safe operation.

- Q: Do cleated belts perform the same as chevron belts?

- A: Cleated belts (applied cleats) and chevron belts (molded ribs) are both designed to handle inclines, but they differ in hygiene, cleat durability, and interaction with certain materials. Molded chevrons are integral to the cover and often last longer in abrasive environments; applied cleats can be replaced individually and are better for certain palletized or packaged goods.

How to Evaluate and Shortlist Chevron Conveyor Belt Suppliers

Start by verifying technical competence: review datasheets, request reference installations, ask for material test reports, and confirm warranty terms. Evaluate logistical capabilities—can they meet your lead times, offer local support, or manage emergency replacement? Confirm quality systems such as ISO certification, and inquire about after-sales service, training, and spare-part availability. Finally, request a sample or small trial order whenever feasible; real-world testing will reveal fit and finish better than brochures alone.

Case Study Snapshot: Typical Improvement When Switching to Chevron

Consider a facility that previously used flat belts for a 25° incline and suffered frequent slippage and spillage. After upgrading to a properly specified chevron belt with a matched compound and pulley lagging, the plant reduced spillage by over 80%, decreased clean-up labor, and increased conveyance throughput by 12%—demonstrating how the right belt and supplier partnership can improve efficiency and safety while cutting operating costs.

Conclusion

Choosing the right chevron conveyor belt and working with knowledgeable chevron conveyor belt suppliers can transform how you handle inclined and challenging bulk materials. Prioritize technical expertise, transparent testing, and post-sale support when evaluating vendors. A carefully specified chevron belt can lower spillage, increase incline angles without redesigning plant layout, and reduce long-term costs—making the upfront selection process one of the most important steps in conveyor planning.